MANUFACTURER OF CASTING & ALLOY

At Shiv Chidambar Industries, we specialize in high-quality alloys and precision castings that power industries worldwide. With years of expertise and advanced technology, we deliver durable, high-performance metal solutions tailored to your exact specifications. Our products meet the highest international standards, ensuring strength, reliability, and efficiency in every cast

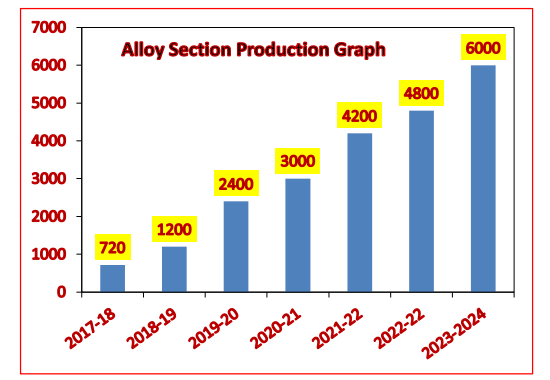

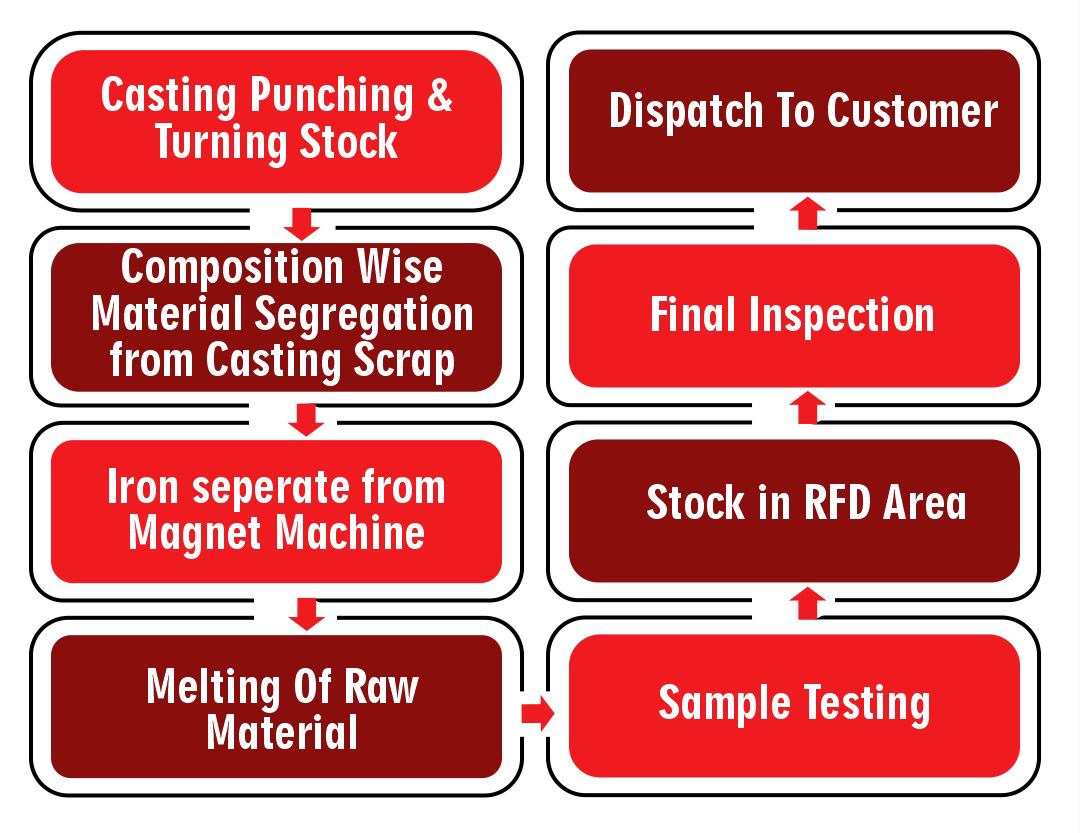

Shiv Chidambar Industries, established in 2017, is an IATF 16949:2016 certified manufacturer specializing in Aluminum Alloys and Gravity Die Castings. With modern GDC machines, spectrometer-based testing, and CNC machining, we deliver precision and reliability across industries. We are leading manufacturer specializing in Gravity Die Castings Production, in our casting Division, a capacity of 200 MT supported

|

We are Experts in Alloy Making & Castings as

per Customers Requirement |

|||

| Sr.No | Grade | Sr.No | Grade |

| 1 | ADC-12 | 11 | ALSI8CU3 |

| 2 | AC2B | 12 | ALSI9CU3 |

| 3 | AC4C | 13 | ALSI7MG |

| 4 | LM-2 | 14 | ALSI10MG |

| 5 | LM-4 | 15 | ALSI9MNMG |

| 6 | LM-6 | 16 | A380 |

| 7 | LM-9 | 17 | A356 |

| 8 | LM-24 | 18 | ADC-3 |

| 9 | LM-27 | 19 | ADC-16 |

6000MT/Annum With 20000 Sq.ft shop floor area

7000 Sq.ft area reserve to Casting section

Customer Satisfaction & Appreciation is our Moto

We are manufacturer of industrial Aluminium Alloy our valuable clients. Aluminium Alloys in many industries, including chemical vessels, the aircraft and aerospace industries as well as ships and vehicles, electrical power etc., are increasingly extensive because of their light weight, their high strength and resistance to corrosion.

We have complete testing facility with latest Optical Emission Spectrophotometer and Atomic Absorption Spectrophotometer to ensure quality of raw materials and Finished Products.

Send a message