At Shiv Chidambar, we take pride in being one of Pune's most reliable aluminium die casting manufacturers, delivering precision-engineered components that power industries across India. With years of hands-on experience in aluminium casting with core sand and advanced die-casting techniques, we serve automotive, electrical, engineering and industrial sectors with commitment to quality and timely delivery.

When you search for an aluminium die casting company in Pune, you're not just looking for a supplier. you're looking for a manufacturing partner who understands your exact specifications, t imelines and quality standards. As a dedicated aluminium die casting manufacturer, we combine traditional craftsmanship with modern technology to produce components that are lightweight, durable and cost-effective.

Our facility is equipped to handle both high-volume production runs and custom projects, ensuring that whether you need 100 pieces or 100,000, each component meets the same exacting standards.

Experience and Industry Expertise

Top manufacturers emphasize their years of service and deep understanding of client needs across

multiple industries. Customers want partners who've solved similar challenges before.

Quality Certifications and Standards

ISO certifications, quality control processes, and adherence to industry standards are consistently

highlighted. This builds trust and assures clients of consistent product quality.

Comprehensive Service Range

The best companies offer end-to-end solutions from design consultation and prototyping to finishing

and delivery. One-stop service saves clients time and coordination effort.

Custom Manufacturing Capabilities

Flexibility to handle custom orders, varied batch sizes, and specific material requirements stands out

as a crucial differentiator.

Transparent Communication and Support

Clear contact information, responsive customer service, and willingness to discuss project details

openly create confidence in potential clients. At Shiv Chidambar, we've built our business around

these exact principles.

As experienced aluminium die casting manufacturers, we use both gravity die casting and pressure die casting methods depending on your component requirements. Our aluminium casting with core sand capability allows us to create complex internal geometries that would be difficult or impossible with standard die casting alone.

This flexibility means we can manufacture:

We work with various aluminium alloys including LM6, LM24, and others, selecting the right material based on your application's strength, weight, and corrosion resistance requirements. Our metallurgical knowledge ensures reliable performance in real-world conditions.

Every casting undergoes rigorous quality checks for dimensional accuracy and surface finish. Our commitment to excellence has earned us the trust of clients across Maharashtra and beyond.

As an established aluminium die casting company in Pune, our optimized processes allow competitive pricing without sacrificing quality. We focus on long-term partnerships, not just transactions.

1. Consultation & Design Review

We begin by understanding your requirements, reviewing technical drawings,

and suggesting improvements where applicable.

2. Tooling & Pattern Making

Our skilled craftsmen create precise dies and patterns, which are essential

for maintaining consistent casting quality.

3. Casting Production

Using appropriate casting methods. whether pressure die casting for high-volume parts or aluminium

casting with core sand for complex geometries, we manufacture your components.

4. Finishing & Quality Inspection

Each component is finished as per specifications and thoroughly inspected

before dispatch to ensure compliance with quality standards.

5. Timely Delivery

We understand that production schedules matter. Our efficient logistics

ensure your components reach you on time, every time.

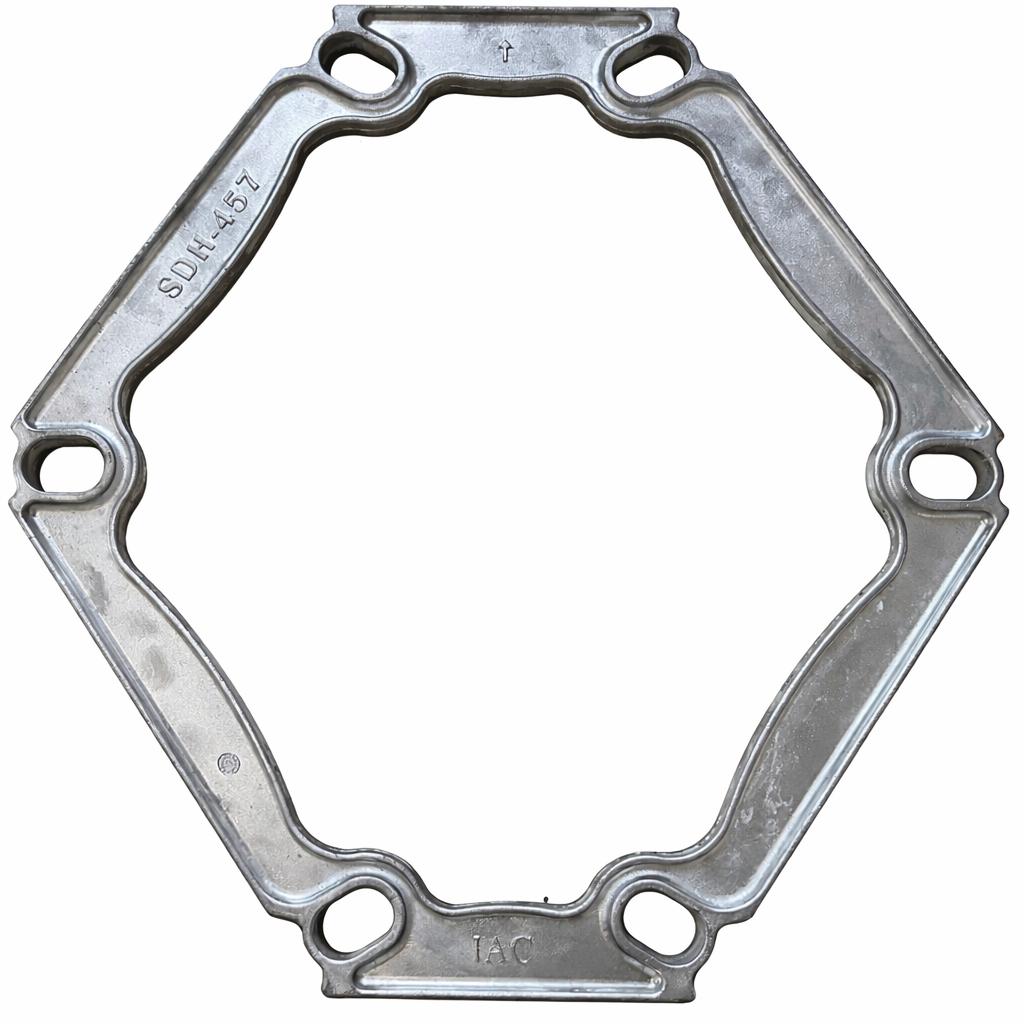

As a versatile aluminium die casting manufacturer, we cater to diverse sectors:

Automotive Industry

Engine parts, transmission components, structural elements

Electrical & Electronics

Junction boxes, motor housings, heat dissipation components

Industrial Equipment

Pump bodies, valve components, machine parts

Construction Hardware

Fittings, brackets, architectural elements

Consumer Products

Appliance components, furniture hardware

At Shiv Chidambar, we don't just manufacture aluminium castings. we build partnerships. When you choose us as your aluminium die casting manufacturers in Pune, you gain:

Reliable Quality

Consistent standards across every batch

Technical Support

Engineering guidance from consultation to production

Flexible Solutions

Custom manufacturing tailored to your needs

Competitive Rates

Fair pricing with transparent quotations

On-Time Delivery

Respect for your production schedules

Whether you're developing a new product or looking for a reliable manufacturing partner for existing components, Shiv Chidambar is ready to support your needs. As a trusted aluminium die casting company in Pune, we invite you to experience the difference that quality craftsmanship and customer-focused service can make.

Contact us today to discuss your project requirements. Our team is ready to provide technical consultation, competitive quotations and solutions that work for your specific application.

A manufacturing process where molten aluminium is injected into steel molds under high pressure to create precise, complex metal parts.

Yes, aluminium is 100% recyclable without quality loss, making it one of the most sustainable manufacturing materials.

Cold chamber is used for aluminium (high melting point), while hot chamber is for low-melting metals like zinc.

Minimum wall thickness is 0.8-1.5mm for pressure die casting and 3-5mm for gravity die casting.

We specialize in die casting, gravity die casting and aluminium casting with core sand technology.

Send a message